This is what your double kick pedal is most likely. 2 U-Joints that connect a slave pedal to the main pedal.

As can be seen in the video, if the angle of the 2 joints is not identical, you can be left with a bothersome lumpy-feel in the movement of your slave pedal.

After the break I’ll show you a couple easy ways to make sure that your U-Joint angles are setup identically to allow for optimal feel.

Read more →

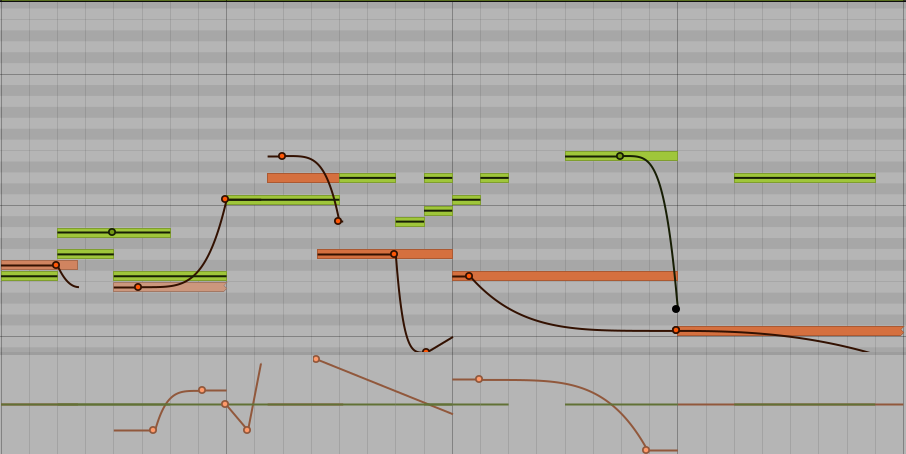

So my first few days of Bitwig have been interesting. I can’t say that it’s been a pleasant experience, but rarely is learning a new DAW.

Remember, these are just first impressions. I will dive in with more detailed analysis and review as this series continues over the next 26 days.

Click through for much more detailed first impressions.

Other posts in this series:

- Bitwig feature review - Note Expression

- Bitwig Modulators - The coolest part of Bitwig

- Bitwig Effects review

- Bitwig Instruments, Note Effects and Instrument Containers Review

- Things that Bitwig could improve.

- Bitwig Conclusion

- Bitwig Review, but better!

You may or may not know, but I have an anonymous electronic music side project. I have used Renoise for this for many years, but in the spirit of my 30 days project, I will be using Bitwig Studio 2.1 for 30 days.

Why now? Well, basically because there’s finally crossfades. Seriously.

I will be doing large reviews like I’ve done for the other DAWs, so check back twice a week for more fun!

Other posts in this series:

- 30 days with FLStudio 20 - Part 0: Introduction to this series

- 30 days with FLStudio 20 - Part 1: Introduction to FL

- 30 days with FLStudio 20 - Part 2: Recording and Editing Audio

- 30 days with FLStudio 20 - Part 3: Piano Roll basics

- 30 days with FLStudio 20 - Part 4: Advanced Piano Roll

- 30 days with FLStudio 20 - Part 5: Piano Roll Tools

- 30 days with FLStudio 20 - Part 6: MIDI Controllers

- 30 days with FLStudio 20 - Part 7: Modulation

- 30 days with FLStudio 20 - Part 8: Performance mode and Video FX

- 30 days with FLStudio 20 - Part 9: Workflow

- 30 days with FLStudio 20 - Part 10: Effects Review

- 30 days with FLStudio 20 - Part 11: Instruments Review

- 30 days with FLStudio 20 - Part 12: Conclusion

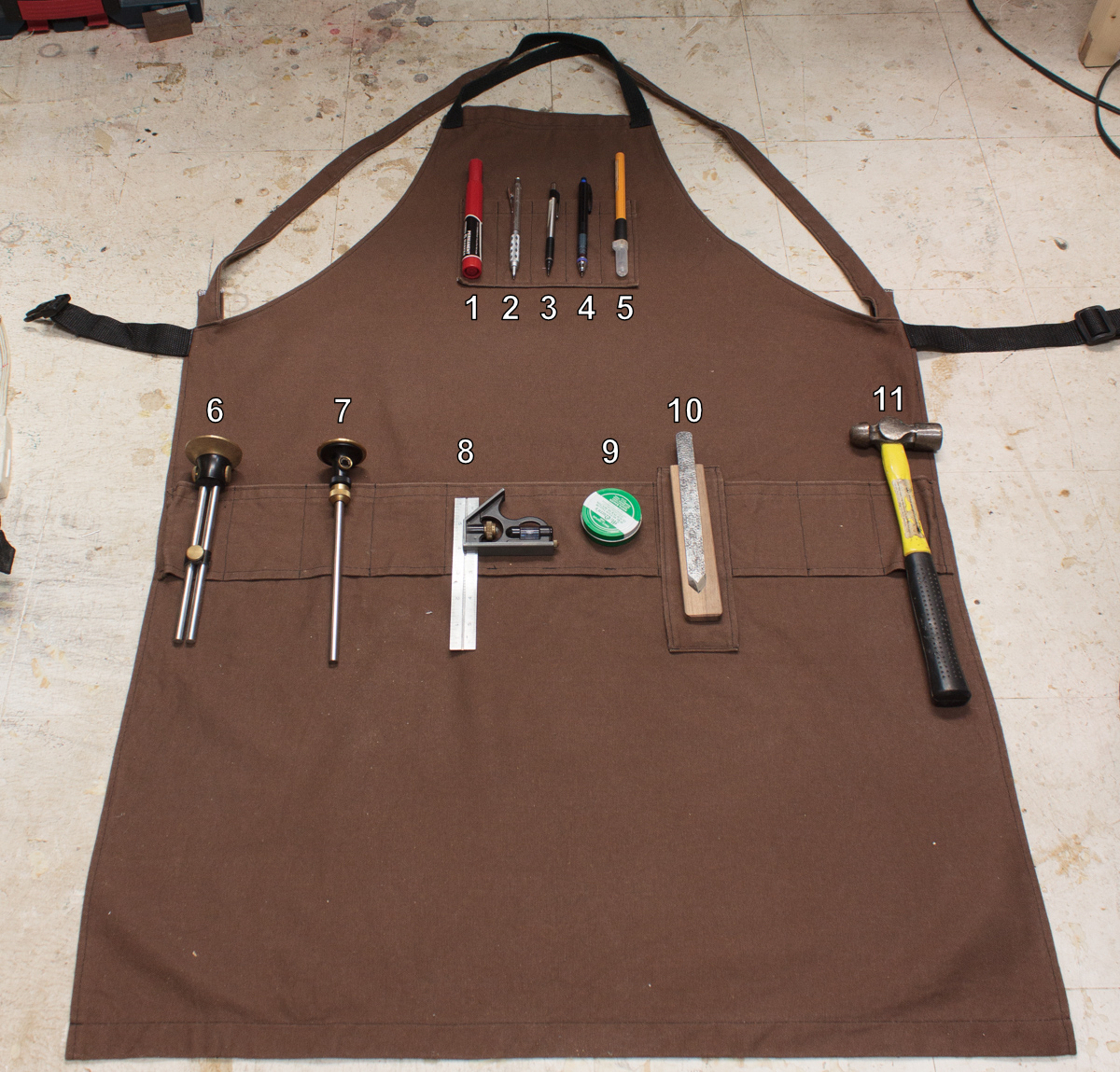

Beautiful and functional apron

Beautiful and functional apron

So here’s my awesome new apron that my wife made for me. It’s a cross-backed apron with locking clips at the waist for holding it snuggly against my body. Custom fit, and it feels so nice to wear even with a bunch of stuff hanging off it.

I can bend, twist, squat, sit and spin in circles without the slightest bit of discomfort despite having a number of commonly used tools on me.

Click through and mouse over the images to see what I’m using in it!

Read more →

My wife made me a great shop apron that I’ll be doing a breakdown of soon. Also some Reaper, Digital Performer and Maybe a Studio One 3.5 post…

However, I’ve had a nasty head cold and I’m still recovering. Expect stuff in the next few days!

I’ve been having difficulty finding the desire to work on my own music lately. So I’ve decided to try something drastic; I will not turn on or seek to listen to any music for 7 days.

That’s a lot for me. I always have music on. Sometimes I’ll have multiple layers of music on. I’m talking 3 or more self-selected sources of music in the same small space.

I use it to drown out my thoughts when they become overbearing. I use it to drown out the soft noises from outdoors that pique my interest and distract me. I use it to mask the noises that startle me. I use it to mask the fan. I use it to waste time. I use it to relieve the frustration of disliking my own musical expressions. I use it to work (on other people’s creations). I use it to explore technical processes. I use it to find practice material. I use it to time myself such as when; cooking, cleaning, exercising or waiting for glue.

What I don’t do with music is listen to it. Actually listen to it. I haven’t done that in decades.

So, I am going to not seek to listen to music for 7 days. I will not avoid it if my wife is listening to it. I will not avoid it in the store. I will not avoid it on streams or such.

I’m on Day 2 now, and it’s surprisingly difficult. My anxiety level has skyrocketed and I’ve gone through enough benzos to kill a horse. Doesn’t matter though.

7 Days

This is why you always use a push block or a pair of push sticks.

I was routing this cove in a piece of Ash. I had featherboards in place and I was using a push block. The router bit caught a wayward grain exclusion which twisted the board slightly between the fence and horizontal featherboard. One face of the cove was then wedged between the router bit and the pressure from the featherboard.

Then BOOM. The workpiece flew across the shop and hit the wall with a loud bang. Click the image above. You can see each point where the router bit grabbed the work as it was flung in to the wall.

My brother curiously suggested that it was going at about 10-15m/s and packing about 40 joules. That would be painful enough if it hit you, but the real danger is if your fingers were pulled in to the router bit.

Stay safe! Even when doing everything right, accidents still happen. It’s up to you to make sure those accidents don’t cost you a finger.

Some people love sharpening. Some people hate it. I like it, but there’s no reason to spend more time doing it than necessary.

If you use water stones then there is a way to reduce time spent on each stone and improve the feeling of moving the steel across the stone.

Click through for how, and some testing!

Read more →

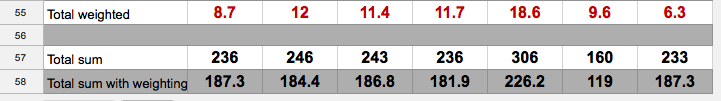

UPDATE: Please see the new DAW Feature Chart for more up-to-date information and a way cooler chart.

It’s time for another DAW Chart!

I’ve spent some time thinking about how I had this setup. Having experienced DAWs that are deficient in some areas, and learning the wonders of other features, I’ve re-evaluated what I feel is important. There’s features that I’ve come to rely on heavily in Reaper, and some features I’ve realized (analytically) that I don’t use as often as I thought.

My time spent in each DAW as a percentage, according to Time Sink has been:

- Reaper - 61%

- DP - 39%

Actual chart after the break…

Read more →

The thing above is a 2-stage stool. It’s a 35.5”/90cm tall bar-stool that allows you to swing your legs back more than normal. It’s also a step stool!

The joinery is almost entirely drawbored mortise and tenon. There’s a decorative doweld-dual-V bridle joint in the center and where your feet sit are half-open dowelled lap joints. The half-open joint allows your feet to rest without the possibility of tearing the end grain of the seat.

The real fun part of this is that the entire stool was made with no power tools of any sort and the material is a single pine 2”x4”x10’ found on the side of the road.

It was glued almost entirely with rice glue that I made. The exception was the seat laminations. The entire structure is sturdy based entirely on the mechanical structure of the joints. The rice glue is just insurance. I’m certain that you could throw it off a building and the joinery would be unscathed.

Now I need to darken the finish to match the kitchen that it’s set to go in, and stabilize a few of the knots with some epoxy.

(shoutout to Darn Tough for making the world’s best socks, and with a no-nonsense lifetime warranty!)