I have cheap chisels. There, I said it. My first set of chisels was the Neiko Chisel set, and I acquired the HF chisels just because I got them on sale for $3. Over time I’ve become rather unhappy with the edge retention of the Neiko chisels, so I recently purchased the Narex.

You can find these chisels at these various locations:

Upon receiving the Narex chisels I decided to do some investigation. First I came up with a test protocol that consisted of the following stages:

- Photograph starting edge.

- Photograph sharpened edge.

- 20 hard, measured chops in hard maple across the grain, as if chopping a mortise.

- Pictures of the edge after the chopping.

Further relevant information:

- All of the chisels were sharpened using Shapton Kuromaku stones in order from #1000▸#5000▸#8000▸#12000.

- I progressed from each stone when I felt a burr and the reflection on the bevel seemed to show that the previous scratches were gone.

- No micro-bevel was used

- The bevel angle is 25°.

- The Lee Valley Honing guide with narrow head was used to maintain very accurate bevel angles. A great product, highly recommended.

- All chisels were the 1/2″ sized.

- All chisels were oiled with camelia oil between stages.

In the following pictures, 1 pixel is 0.11732µm in size. For reference, the average human hair is 50µm. Even though the images are shown resized, these photos are quite detailed!

You can view the full-sized images right here or you can click the images to see them in full size.

The photos were taken by Steven Randolph.

What follows is the results of that test, with commentary following each image.

Starting edges!

Narex Factory Edge

The factory edge clearly has a small micro bevel, and it can be seen that the burr is rolled form the back. This initially indicated to me that the tip of the back had been touched with a buffer+compound at the factory. When flattening this was confirmed by noting a small bevel on the back of the chisel at the tip. This is not good!

The factory scratches appear to be consistent with around #320 on the main bevel and ~#1000 on the microbevel. The microbevel has not been worked enough to remove the ridges from the main bevel’s deep #320 scratches.

Neiko shop used edge

What a disaster this thing is. That schmutz on the edge is corrosion and rust. I kept this chisel well oiled and no matter what I do, it collects corrosion.

Despite the relatively fine looking edge, which is the result of stropping as I used it, it feels dull in use.

Harbor Freight shop used edge

This chisel has been used in the shop frequently, where I use a strop with Herb’s Yellowstone Compound, a product I like very much. This chisel easily pops hairs off your arm at this point despite the non-linear edge profile.

New edges

Narex new edge Attempt #1

This was my first attempt at sharpening the Narex chisel. I was very unhappy with the job I did, despite the burr formation and scratch removal appearing to be correct as I moved between grits.

I suspect the factory grind caused me a lot of trouble here, but I also wouldn’t rule out my own incompetence somehow. I had a lot of difficult working in the low-light of the photography location.

I will note that I was very annoyed with myself for producing this edge.

Strokes required -

- #1k - 25

- #5k - 20

- #8k - 10

- #12k - 15

Narex new edge Attempt #2

OK. That’s more like it! I followed the same number of strokes on the stone progression as before.

You can still see that there are some deep scratches from previous grits present. It appeared rather difficult to get rid of these. It seemed like the stones were burnishing the peaks the grit left behind rather than cutting.

Strokes required -

- #1k - 25

- #5k - 20

- #8k - 10

- #12k - 15

Neiko new edge

Yes you can see corrosion. Why? I don’t know, because this sat OILED for about 10 minutes before the photo was taken. You can also see some defects in the edge where I suspect there was carbides popping out.

Strokes required -

- #1k - 60

- #5k - 40

- #8k - 60

- #12k - 100

Harbor Freight new edge

Very clean with some very slight corrosion.

Strokes required -

- #1k - 12

- #5k - 12

- #8k - 13

- #12k - 10 No, those are not mistypes. Extremely easy to sharpen. Which would make you think that… well, we’ll get to that.

20 chops later…

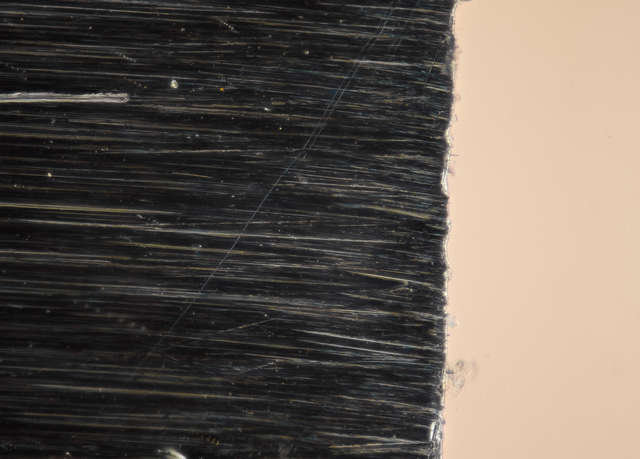

Narex 20 chops edge

The edge rolled on this chisel. At this point it felt the dullest of the lot, however when I got back to my shop later it was partially resurrected with a good stropping.

The issue here is that the non-linear edge will be increasingly susceptible to rolling again, and eventually chipping due to work hardening of the edge.

I have a feeling that this chisel would likely perform well with a 30°+ microbevel to reduce the edge rolling. I am currently testing this in the shop.

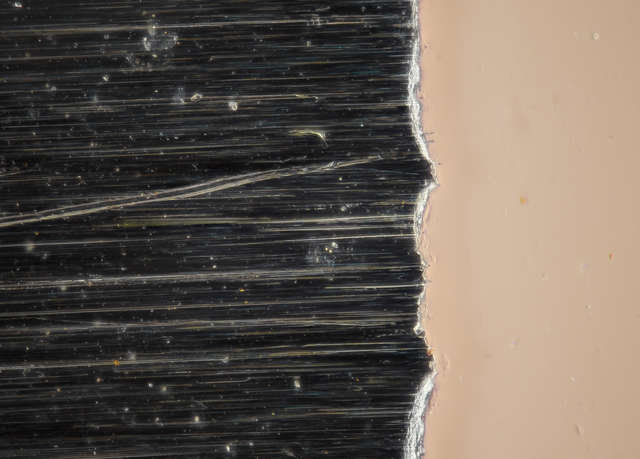

Neiko 20 chops edge

A disappointment. The edge is chipped rather severely. It’s hard to tell from this picture, but there are various small chips that bevel in both directions from the edge. If you look near the center, you can see the transition from forward facing bevel on the chip, to backward facing. This means that the back must be re-flattened to re-attain a satisfactory edge.

Take note that the edge here is chipped, not rolled. A rolled edge can be brought back with careful stropping. A chipped edge requires a regrind.

This is clearly the worst performing here.

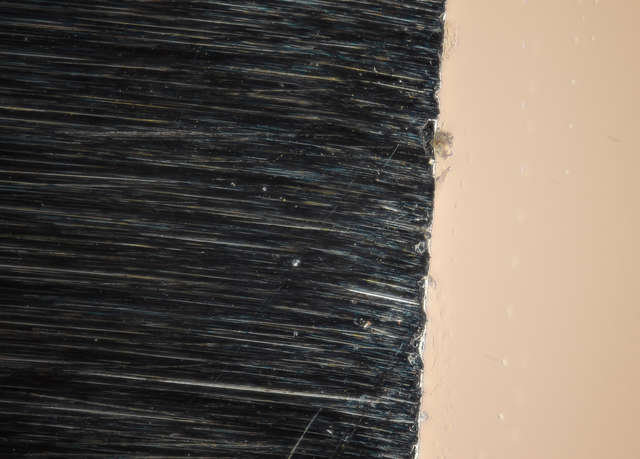

Harbor Freight 20 chops edge

This is not a mistake. I did upload the correct image. It still even shaves.

I’ll leave you with that.

Non-test observations

Harbor Freight - I disliked the handle the most out of all of them. The non-cutting edges of the chisel arrived with a very sharp burr. They do not feel balanced in use. Aside from the cutting performance, they feel like cheap chisels.

The cutting edge arrived very out-of-square on these.

The edge protectors fit nicely.

Neiko - The handles on these are crooked! It is incredibly annoying to pick up the mostly-square chisel handle and have the bevel not line up with your grip. The handle is also slippery, especially when sweaty. All of the edges on these chisels are sharp.

When these arrived, ALL of the cutting edges were chipped in transit. They were also not square.

The edge protectors fit nicely.

Narex - These are the nicest to use. The handles feel nice and they are attached correctly. Hitting them with a mallet is pleasant. I am quite happy using these as a matter of feel.

The factory edge was square and they were packed extremely well by Lee-Valley.

The edge protectors fit very poorly, but I modded them to work nicely.

Conclusions

I think that the conclusions here are quite obvious. The winners are…

Harbor Freight Narex Neiko The Harbor Freight chisel is some sort of freak. It required the least effort to sharpen and it held up the best in the chopping task. Why? I really have no clue. These things only cost me $0.75 when I purchased them! The currently are listed at $2 each (4 for $7.99). I have a feeling that the HF chisels edge failure would be catastrophic rather than gradual as the others shown. However, for this test it was the clear winner.

The Narex chisel needs more shop testing I think. I currently have a 32° microbevel on them in the shop and they are performing alright. I will hopefully revisit this at another time perhaps.

Neiko chisels… stay away. The evidence speaks for itself. Difficult to sharpen and the edge breaks easily.etc..

I’m sure there were some errors in this, and I hope to revisit this again with some higher-quality (or perhaps just higher-priced!) products.

Thank you for reading.