I made some quite decent turning tools in the style of the Easy Wood Tools for less than 1/3 the price. I also think mine are much prettier.

I documented the process so perhaps you too can have some great turning tools at a low cost!

Contents

- Purchase

- Prepared

- Prepare to drill

- Drill

- Turn

- Cut the ferrules

- Glue the ferrules

- Square it up again

- Polish the ferrule

- Finish

- Insert

- We’re done!

- Support me!

Purchase

The very first thing you need is to buy some sort of carbide insert holder, or you can make one.

I looked in to making my own, and I found that for the price of the metal, shipping and my time, it would be better to purchase this part premade. I strongly suggest checking out Mad Wood Tools on eBay. I purchased their 3 tool set and I’m very satisfied with it.

An excellent source of carbide inserts is Eddie Castelin

You will also need something to make ferrules so the end grain does not split when you insert the carbide insert holder piece into the wood. I simply used a piece of copper pipe from Home Depot.

Prepared

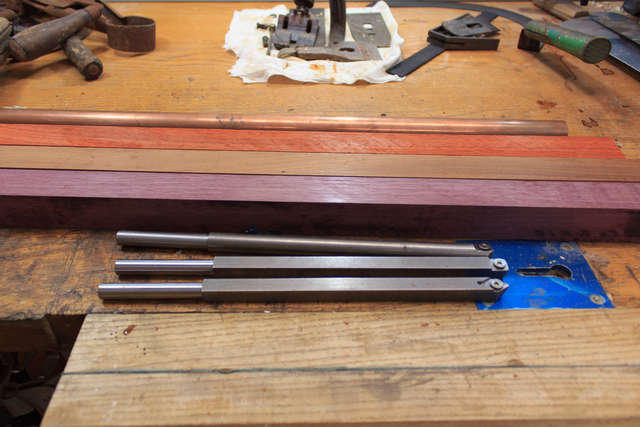

These are the supplies you will need, along with some epoxy, sanding supplies and a lathe.

My handle stock has been squared up to 1.5”x1.5”. They are 16” long. The woods I’m using are (from top to bottom): Padauk, Sapele, and Purpleheart

Prepare to drill

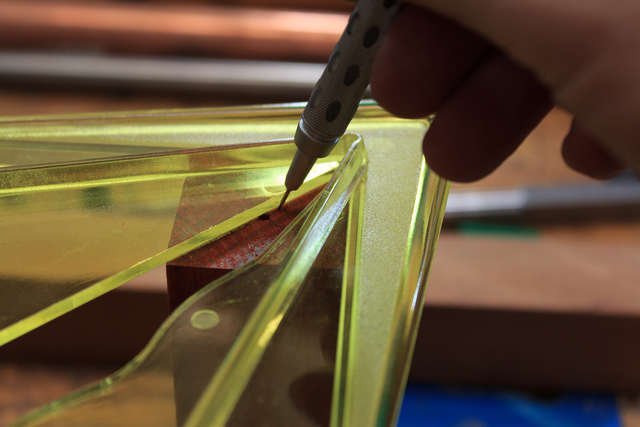

The first thing we need to do is mark a center hole in the stock for drilling. I do a rather poor job here. I need to sharpen my Japanese Awl.

I used a Center Finder to locate the center of the stock. I absolutely love this center finder. I use it all the time.

Drill

So you can see here how I set up the drill press. I have a small drill press that does not have a 16” capacity.

I first unscrewed the base and turned it sideways so the base wasn’t in the way. Then I clamped a square piece of stock to the drill press table, and clamped my work to that.

Get everything plumb and drill away! The carbide insert holders I used have a 1/2” shank. So I started the hole with a 1/2” forstner bit and finished with a 1/2” jobber.

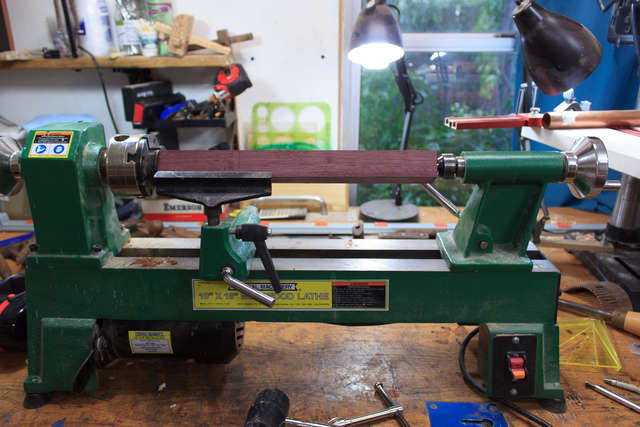

Turn

Now all you need to do is turn some handles. How you do this is up to you. Mine have about a 3/8” slope down to 5” from the butt.

Make sure you carefully turn an end for your ferrules.

You can use your carbide bit holders to turn with at this point if you don’t have any other turning tools. In the interest of someone reading this tutorial having no lathe tools at all, I ended up doing that and it worked very nicely.

When you are done, your blanks should look something like this.

Cut the ferrules

Now just cut your copper to the length you need. I simply used a jigsaw with a bimetal blade.

Once it’s cut, I strongly suggest squaring up your cut with some files or a sander. I used files here.

Glue the ferrules

Here’s a quick shot of how I like to mix small batches of epoxy. I simply put some aluminum foil on a scale and measure out the resin and hardner to 2 different sections. Make sure you look up the weight ratio of your epoxy. It’s often not the same as the volume mixture. This epoxy is 1:1 by volume and 100:84 by weight. This is important

Use 2 different sticks! One for the resin, one for the hardener.

Use yet another stick for mixing the two.

Here I use a heat gun to both cause the epoxy to thin and flow in to the gaps, and accelerate the curing.

Now clamp everything up.

When you’re done everything should look about like this here.

Square it up again

Here I use my previously blogged about disc sander to square up the ferrules that I glued on.

They should end up looking nice and clean when you are done.

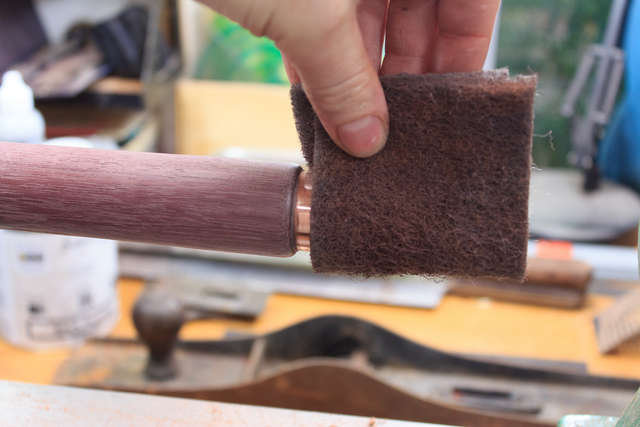

Polish the ferrule

Using some maroon scotchbrite from enco, I both am sanding and heating up the ferrule.

It’s important to heat up the ferrule in this case because I apply a Chromium Oxide buffing compound. Allowing it to melt on makes for a nicer polish in my experience.

Then just apply a shoptowel to it and let the polish do its thing.

Finish

Here are 2 little tricks for you when finishing. Firstly I put 3 bolts in my vise so that I can dry the handles easily.

The second thing is using Kimwipes for applying wipe-on shellac. No lint, no hassle. I discovered this after becoming frustrated with small bits of lint or dust ending up on my finishes from every other type of towel or cloth. These solve that issue.

When you are done, you should end up with a nice deep finish, that also has a fantastic feeling grip.

Insert

Here’s another trick to help you out. I freeze the carbide bit holders in a bag overnight till they are nice and chilly. This very slightly shrinks the metal, which makes it easier to insert in to your bored holes.

Make sure you remove all the air from the bag or you will get small rust spots. If you do get these, simply scrub them off with some 320 sandpaper or maroon scrotchbrite.

Once they warm back up to room temp, they will be firmly attached via friction. NO glue needed. This of course depends on the size of the shank and your drill-bit. My shanks were very slightly oversized, and my drill bit was dead on.

You can of course glue them on if you wish, but I’ve found that this isn’t necessary at all if you use the freeze method with a very tight fit.

We’re done!

That’s it. If you haven’t put your carbide inserts in, do it now.

I assigned my rougher to the heaviest handle, the smoother to the middle-weight, and the detailer to the lightweight. Not really a big deal since they were 5 grams apart from each other! Fanastic tools. Total cost of $110. That is less than the cost of a single equivalent Easy Wood Tool. I don’t think you can beat that, and they don’t come in fancy colour coded woods!

This project took me approximately 4 hours, including time for finish and epoxy to dry.

I was just notified that the fellow on IRC that gave me the idea, through his adamant recommendation of NOT doing this, fell in to a coma recently. How unfortunate.

Support me!

If you appreciate the information presented then please consider joining patreon or donating!