Recently I came in to possession of a Laguna Resaw King bandsaw blade. I heard that it leaves tablesaw-like quality cuts, and would be superior to my Spectrum Supply KerfMaster or Highland Woodslicer.

So to test this, I took a piece of Jatoba which is a wood I use very often, and rip cut it on the same Grizzly G0555X with a riser block with various blades. I timed myself to try and keep the feed rate identical. From there I also prepared samples with low, medium and high angle blade setups in my Veritas bevel-up smoother, my tablesaw with a Dewalt DW7140PT blade, and both sides of a Gyokucho Ryoba for hardwoods.

From there I took macro photographs of each sample in the same lighting. I used a Canon 600d with a EF-S 18-55mm f/3.5-5.6 IS on a Reversing Ring. The angle of some photos is changed slightly to help accentuate certain details. You may notice a large variation in colour across the photos, but that is representative of the changes in the wood itself as a result of the preparation method! The frame size is ~4mm.

I’ve organized the images in order from what I feel is worst quality finish to best.

Let’s get on to it…

Contents

- Laguna Resaw King

- Spectrum Supply Kerfmaster

- Highland Woodslicer

- Ryoba Rip

- Ryoba Crosscut

- Tablesaw

- Veritas Low Angle

- Veritas Medium Angle

- Veritas High Angle

- Conclusion

- Support Me!

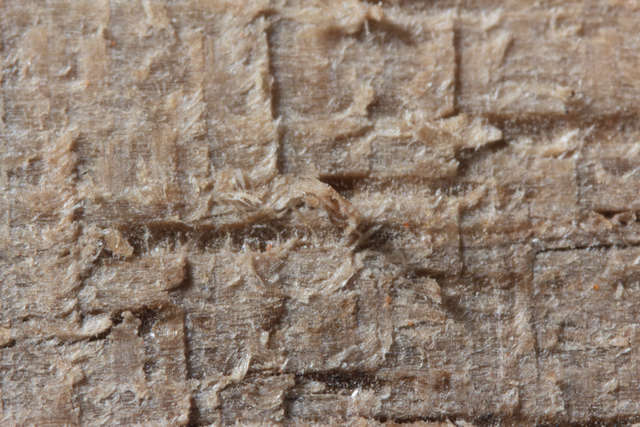

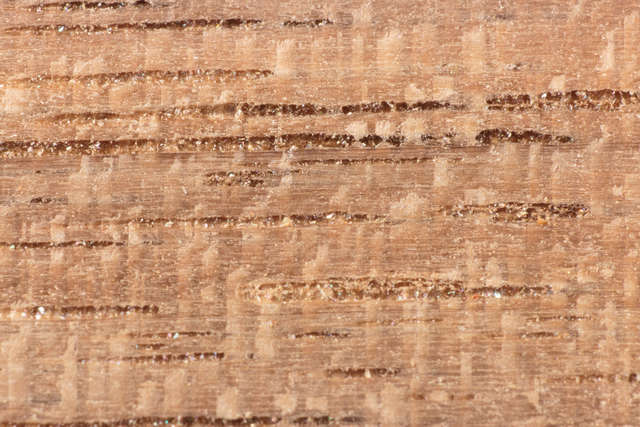

Laguna Resaw King

The Laguna Resaw King should produce better quality cuts than hardened steel blades. However I was unable to do so on this saw.

It took a lot of effort to properly tension the blade, re-adjust the wheels and setup the guides. Even with all that effort the cut effort was slightly rough and the result was not ideal.

The cut quality is rather poor. Large chunks of tear out, deep saw marks and a rough feeling to the touch. Out of a dozen attempts and very careful setup, this was the best result.

I think the take away is that it is not optimal to try and use this blade on a 14” bandsaw. The blade is very likely a fine product, however I was unable to use it properly on my saw and this is the result of such a mismatch.

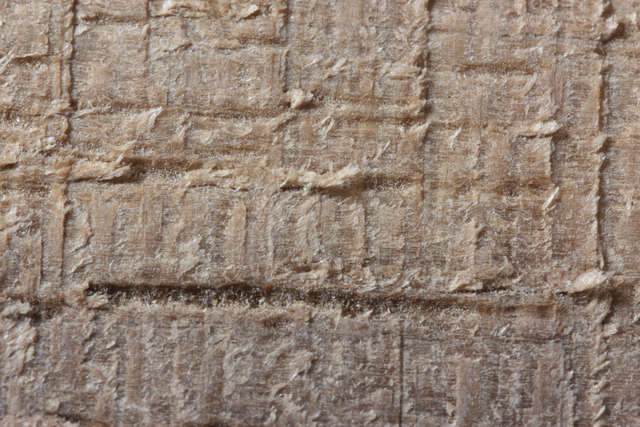

Spectrum Supply Kerfmaster

First up we have the Spectrum Supply KerfMaster, which as far as I know is basically the OEM of the Highland Woodslicer.

The cut quality from a distance is not too bad, however there is some tearout. The blade marks are visible upon close inspection and the natural chatoyancy of the wood is not present.

I’m unsure of what those bits of red are in the photo.

I used the 1/2 x 0.022 x 3/4T x 105” blade.

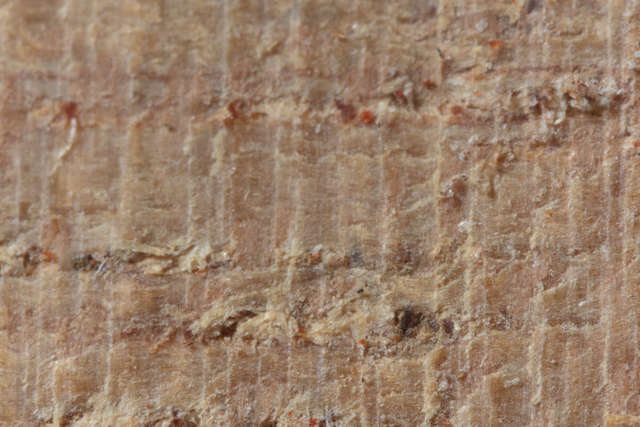

Highland Woodslicer

The Highland Woodslicer promises, “We’ve never seen a resawing bandsaw blade cut this smoothly, and we’re willing to bet you haven’t either.”

This is the case in my experience, but that isn’t saying too much. The specific blade I have does cut very slightly better than the KerfMaster. The tear out is less severe and the bandsaw marks are less prominent.

The woodslicer seemed slightly more difficult to push through the cut, however I suspect this may be due to the specific area of the wood being cut.

I used the 1/2”x105” blade.

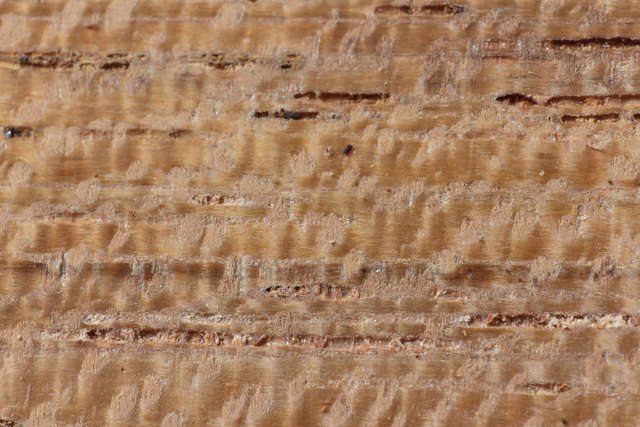

Ryoba Rip

This is the first cut with the Gyokucho Ryoba for hardwoods. I used the rip side for this cut, and this is my preferred method of crosscutting wood usually, so I’m fairly well practiced and accurate with it.

The result feels fairly smooth to the touch with very minimal tear out. The saw marks are closer together than the bandsaw result, but further apart than the crosscut attempt, which indicates the cutting speed.

The colour of the wood is a bit deeper than the bandsaw samples, but the chatoyancy is still not present.

This was the easiest result to plane to a finish I’d feel is satisfactory as a planed surface. It had almost no vacancy in the vessels of the wood and left a very flat surface. I began all of the plane samples with the Ryoba Rip.

Ryoba Crosscut

I used the crosscut side of the Gyokucho Ryoba for hardwoods for this cut.

The saw marks are closer together, which indicates a slower cutting speed. There’s a bit more tear out and for some reason none of the crosscut samples felt as smooth as the rip samples, despite looking fairly similar.

The crosscut side produced rip cuts that were nowhere near as straight as the rip side. Despite my best efforts I always drifted slightly with the crosscut side. The rip cuts were nearly perfect.

Tablesaw

Surprisingly the cut using the Dewalt DW7140PT in my Bosch 4100 tablesaw was rather good.

There is very light vessel tearing that is complete and leaves a smooth surface. The chatoyancy has returned. There is some fiber springback that is seen as waves in the wood. Those waves can be felt to the touch as a light texture.

I first attempted to use the tablesaw samples as preparation for the planing samples, however the vessel tear out required more passes of the plane to achieve a satisfactory surface. For this reason I’ve rated the table saw result as worse than the Ryoba results even though the look is much nicer.

Veritas Low Angle

This is the result using a 25° blade with a 1° microbevel and a 12° bedding in my Veritas bevel-up smoother. The mouth was set very closed with the lightest cut possible. The blade was freshly sharpened before each sample.

This has some of the vessel tearing like the tablesaw result, however there’s less little fiber spring back. The result feels smooth, but the colour is dull.

Veritas Medium Angle

This is the result using a 35° blade with a 2° primary microbevel, 1° secondary microbevel and a 12° bedding in my Veritas bevel-up smoother.

There is more vessel tearing than the low angle result, however the colour and feel is improved. I suspect the increased tear out is a result of the section of wood being planed. The sample I selected to show was the nicest feeling despite the tear out.

This example has the second nicest colour of all the samples and I would feel comfortable moving to filling and finish from this.

Veritas High Angle

This is the result using a 50° blade with a 2° primary microbevel, 2° secondary microbevel and a 12° bedding in my Veritas bevel-up smoother.

This is the example where you can see where the tear out in all of the previous examples stems from. There’s vessels in the wood that are partially filled. Other cutting methods remove this filling (of what I assume is dried sap and/or resin). The 66° plane blade cuts very smoothly and leaves these vessel’s contents mostly intact.

There is some slight fiber spring back. I assume this is from how much physical effort was necessary to take a proper full-width shaving with this blade. The visual result though is brilliant. The wood shines with varying reflections like a puddle of gasoline on the tarmac on a rainy day.

This result required the most passes with the plane, and a fairly significant amount of physical effort. The result is the most brilliant and nicest to touch though.

Conclusion

Long story short; I’m sticking with my Ryoba and hand plane. I’ll still use a KerfMaster for long boards and large resaws.

I took the Resaw King back to the store because it required so much effort to setup, and the effort to change the bandsaw back over another blade was even more effort. I don’t see this as the fault of the Resaw King, but it certainly is not appropriate for a Delta-style 14” bandsaw. Maybe one day I’ll find out for sure on an appropriate saw.

For now though, these are the results I was capable of generating with the tools at my disposal.

Support Me!

This post took 19 hours to research, photograph, write and edit. If you appreciate the information presented then please consider joining patreon or donating!